• Due to Covid, A/O June 2021, Lifeline Lead Time may be 2-10 weeks before shipment is possible

FYI, as SOP, Battery replacement should be initiated 3-6 months before they are actually required

vs being an emergency replacement item.

• Sun Xtender Solar Battery information starts apx. 3/4 way down

• Do not miss the FAQ on Lithium Batteries

ZRD sells the Lifeline series of AGM batteries because they are the premier manufacturer of AGM batteries. There are numerous

features and advantages of Lifeline AGM batteries over standard flooded (wet) cells and GEL batteries. At the bottom below, is a more detail explanation of the three

battery types. Some of the main differences between the old vented lead acid batteries and the LIFELINE AGM valve regulated sealed lead acid batteries are:

DETAILS

|

• The electrolyte is absorbed in a glass mat separator in LIFELINE AGMs and is spillable in the flooded or vented type.

• The cells have pressure relief valves in LIFELINE AGMs that are designed to keep positive pressure in each cell. The older vented or flooded type battery cells are open to the atmosphere through the vent cap holes (should the vented battery be tilted or inverted, the result can be electrolyte (sulfuric acid/water mixture) spilled all over your equipment, a highly corrosive and potentially dangerous condition). • The cell groups in the old vented type batteries are loosely packed and thus have high plate separation. In contrast, the LIFELINE AGM marine battery has every square inch of positive and negative plate material tightly packed and compressed with the AGM material and supported by the walls of each cell. With this type of construction, LIFELINE offers much lower internal resistance ... greater starting power (particularly in cold temperature) ... and a much higher degree of protection against shock and vibration than the old flooded type. • In addition, there is not a limiting current for charging. This will greatly reducing charging time required to recharge a depleted house bank. Please contact us for additional detailed information. |

Click to enlarge |

|

Click to enlarge |

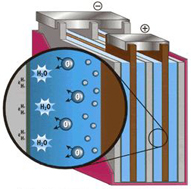

Pictured (above left) is a cross section of a Lifeline battery showing the details that were listed above.

Pictured (above center) are few of the batteries from the product line. The full line is detailed below.

Pictured (above right) is a customer's motor home with six 30HT (900Ah) installed. The small extra black wire is a sensor providing temperature input to the charging source. This customer chose to have the optional screw-in terminal post extensions installed. They allow either automotive post connection wiring or flush fit blade wiring to be used. This option is battery dependent.

Pictured (above center) are few of the batteries from the product line. The full line is detailed below.

Pictured (above right) is a customer's motor home with six 30HT (900Ah) installed. The small extra black wire is a sensor providing temperature input to the charging source. This customer chose to have the optional screw-in terminal post extensions installed. They allow either automotive post connection wiring or flush fit blade wiring to be used. This option is battery dependent.

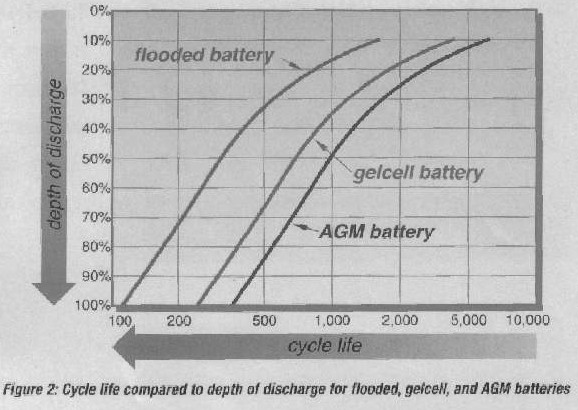

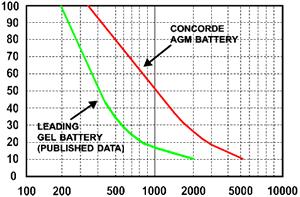

Life Cycle Performance Comparison

|

|

Pictured above are two graphs comparing the life cycle performance of different battery types. It should be evident why AGMs are the clear choice.

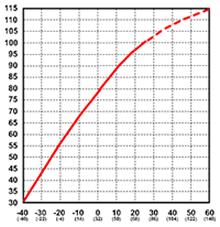

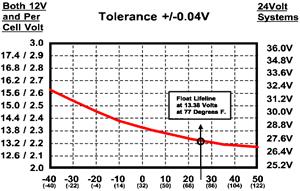

Temperature Influences

Battery Capacity at

|

Charge Voltage/Ambient

|

Pictured above are two graphs showing the influence of temperature on Battery Capacity and Charging Curves. The importance of battery temperature monitor input into

three stage charging becomes evident.

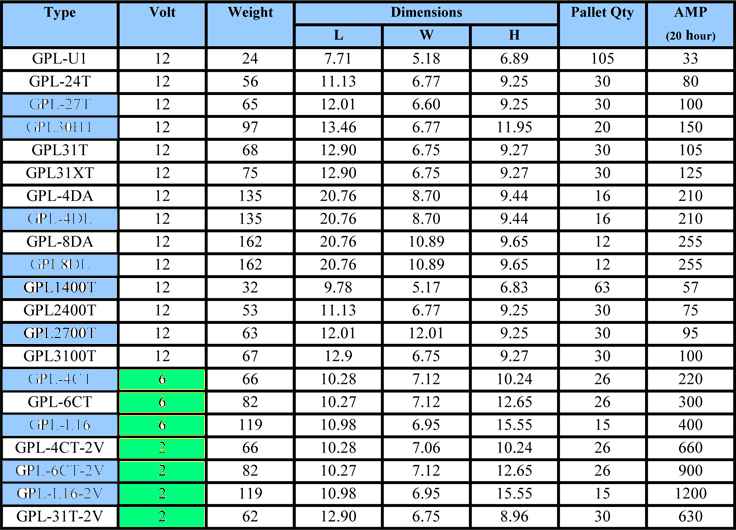

Below is a table showing the specifications for the various sizes of current Lifeline battery products. Please contact us for any assistance. To aid in your selection, the items in Bold are recommended for most installations. The most Commonly Used sizes and their most significant specification are highlighted in light blue. 6v and 2v are highlighted in Green.

Manufacturer Specifications and Pricing may change at any time due to the price of Lead.

| * NOTE: Substantial discounts are provided for Retail Pricing starting at a quantity of one (1). Additional discounts become progressively greater as order quantities increase (2, 3, 4, 6+). All orders are plus direct S&H to your location. For Florida deliveries, Sales Tax and a Battery Disposal Fee of $1.50 per battery are additional charges. Contact us for your total pricing solution. |

Below is a table showing the specifications for the various sizes of current Lifeline battery products. Please contact us for any assistance. To aid in your selection, the items in Bold are recommended for most installations. The most Commonly Used sizes and their most significant specification are highlighted in light blue. 6v and 2v are highlighted in Green.

HOUSE BANK and MARINE STARTING APPLICATIONS

Above information provided by Lifeline Batteries

Click here to view a large Detailed image of the four (4) different types of Battery Terminals.

| Part Number | Terminal Types |

| GPL-24T, GPL2400T, GPL27T, | Marine Terminal (Copper Alloy) |

| GPL-2700T, GPL-31T, GPL-3100T | Pos Terminal=M10, Neg Terminal=M8 |

| GPL-4DL, GPL-8DL | L-Blade Terminal (Solid Copper) w/M8 Hardware |

| GPL-4DA, GPL-8DA | A- SAE Post Automotive (Lead Alloy) |

| GPL-4CT, GPL-6CT, GPL-1400T | M8 Threaded Insert (Copper Alloy) |

| GPL-U1T | M6 Threaded Insert (Copper Alloy) |

| Optional Terminals: | GPL-4CT & GPL-6CT are available (special order) with Marine Terminals. |

| Metric/U.S sizes: | Nearest U.S. Dimensions: M6 = 1/4", M8 = 5/16", M10 = 3/8" (U.S. reference sizes only, not interchangeable). |

| Torque Values: | (M6 use 35 in-lbs / 4.0 Nm) (M8 & M10 use 70 in-lbs / 7.9 Nm) |

| Terminal Hardware: | When required, all batteries are supplied with silicon bronze bolts, nuts & washers necessary for installation. |

| Handles: | All part numbers include carrying or lifting handles. |

| Ratings: | Capacity ratings are after 15 cycles & are at 77°F (25°C) to 1.75 volts per cell. |

| Note: | Never install batteries in an unventilated compartment or a sealed compartment or sealed container |

A Detailed Comparison of Battery Types

|

Today, there are three distinct types of lead acid batteries manufactured and any one type can

be designed and built for either starting or deep cycle applications. These types are flooded acid, gelled acid, and Advanced AGM (Absorbed Glass Mat). There are

various quality levels available in each type. Price is dependent upon the perceived quality as well as the product design, processing, and manufacturing costs.

This includes the amount of lead, methods of pasting and curing the plates, degree and type of inter-plate insulation, quality of the case, and the sealing method used.

Generally, high quality means higher cost.

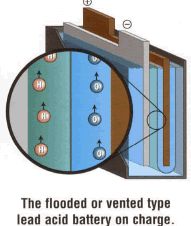

The oldest types of lead acid batteries are flooded cell types. These have been around for decades. The liquid sulfuric acid solution in these batteries has destroyed more than a few sets of clothes and pieces of RV gear. They generate and vent dangerous explosive gases, acid "mist" during charging, corrode their terminals, often-acid damage surrounding surfaces, and require regular watering. They have the least expensive initial cost. |

|

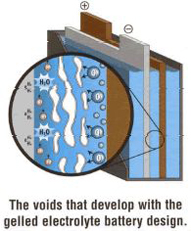

The next types of batteries are gelled acid (Electrolyte) designs. They were introduced over 30 years ago and widely touted for their increased efficiency and designed safety features. Their acid is immobilized by adding "fumed" silica to the sulfuric acid solution and then sealing the battery. They internally recombine most of the gases (hydrogen and oxygen) generated during charging and are maintenance free. Gelled electrolyte battery designs are generally quite old and few engineering options are left to improve them. Gel electrolyte is highly viscous and during charge and discharge the gel can develop voids or cracks. These impede acid flow and result in the loss of battery capacity. Also the gelled mixture can liquefy upon charge due to the shearing action of gassing (this property is called thixotropic"). After termination of charge, it can take an hour for the acid to gel again. During this time liquid is moving and the battery can leak if any opening has developed. Last, gel batteries may store hydrogen gas that has not recombined. When overcharging causes a gel battery's vent caps to open, explosive gasses may be vented into the battery compartment. This vented hydrogen has caused a number of "fast failures" or battery explosions. |

|

The latest and most advanced battery technology is Advanced AGM, which was developed to

provide increased safety, efficiency, and durability over all existing battery types. In Advanced AGM

batteries the acid is absorbed into a very fine glass mat that is never free to slosh around. Secondly,

since the plates are kept only "moist" with electrolyte, gas recombination is more efficient. (99% AGM).

Thirdly, since the AGM material has an extremely low electrical resistance, the battery delivers much

higher power and efficiency than the other two types. Last, Advanced AGM batteries offer exceptional life

cycles.

Recombinant gas technology was brought to state-of the-art status at Concorde Battery Corporation, one of the world's leading suppliers of sealed aviation batteries. The first AGM, "Air Worthy" batteries were delivered to the U.S. Military in 1985 and today are used on the Stealth Bomber, F- 18 fighter jet, and in other demanding military applications. The heavier "fat plate" "Lifelines" were introduced in 1989. Today, "Lifelines" are the most advanced batteries manufactured in the world. They are subject to the same high standards of design and manufacture as required by FAA and Military Specifications. Additionally, "Lifeline" is the only Advanced AGM product available in standard battery configuration and sizes. They are standard equipment on many U.S. Navy crafts, fine yachts and coach manufacturers. |

Complicated graphs and comparison charts are not necessary to compare the three battery types. Consider:

|

• Batteries can be dangerous. They store a tremendous amount of energy, create explosive gas during charge and

discharge, and contain dangerous chemicals. Some designs and construction techniques are safer than others are. Both

Gel and Lifeline Advanced AGM are sealed batteries that use recombinant gas technology. Lifeline Advanced AGM is more

efficient in the AGM process and completes its gas recombination near the plates. In fact, they are the only batteries

to pass the rigid MILITARY-SPECIFICATION for non-gassing even during severe overcharge. A recent Coast Guard Advisory

warned all users of Gel recombinant gas batteries to install automatic temperature compensated voltage regulators to

prevent explosions associated with their overcharging. Flooded batteries will spew acid, will definitely spill and leak

if tipped over, and they generate dangerous and noxious explosive gases. "Lifeline" Advanced AGM batteries are best at

protecting both equipment and passengers.

• Longevity: All batteries die. The number of cycles it takes to kill them is a function of the type and quality of the battery. When cycled at between 25 to 50 percent depth of discharge (recommended deep cycle use) "Lifeline "Advanced AGM batteries will normally easily outlast the other two types. • Durability: Some battery designs are simply more durable than others are. They are more forgiving in abusive conditions, i.e.; they are less susceptible to vibration and shock damage, over charging, and deeper discharge damage. Gel acid batteries are the most likely to suffer irreversible damage from overcharging. Flooded acid batteries are the most likely to suffer from internal shorting and vibration damage. Lifeline Advanced AGM batteries are more durable and can withstand severe vibration, shocks, and fast charging. • Efficiency: This comparison is critical. Internal resistance of a battery denotes its overall charge/discharge efficiency, its ability to deliver high cranking currents without significant drops in voltage, and is a measure of how well it has been designed and manufactured. Internal resistance in NiCad batteries is approximately 40%, i.e., you need to charge a NiCad 140% of its rated capacity to have it fully charged. For flooded wet batteries, internal resistance can be as high as 26%, which is the charging current lost to gassing, or breaking up of water. Gel acid batteries are better at only approximately 16% internal resistance and require only roughly 116% of rated capacity to be fully charged. Lifeline Advanced AGM has the lowest internal resistance of any battery manufactured only 2 percent. This allows Lifelines to be charged much faster if needed and also to deliver higher power when required. Owners using high output alternators, operating inverter banks, or relying on solar panels can benefit significantly when using Lifeline Advanced AGM batteries with their equipment. "Lifelines" are more efficient!! • Battery Measurements: Most buyers like to make comparisons by using various specifications and measurements. A few common comparison criteria are Cold Cranking Amps or CCA, which is a clear indicator of a battery's ability to start an engine. Reserve Minutes depict a battery's ability to deliver current at steady rates from a fully charged condition down to 10.5 volts and are expressed in minutes, i.e., reserve minutes at 25 amp discharge. Life Cycles are used to measure longevity or how many times a battery can be discharged in its life time at set levels. |

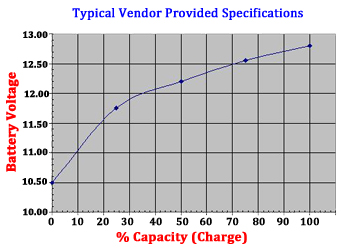

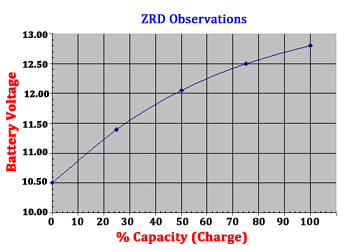

Analysis of Battery Capacity

Below are data tables and their resultant graphical representations of % Battery Capacity versus Measured Battery Voltage. The major difference between the data sets is that in most scenarios, lab testing data will exceed field results. When analyzing the data, one will notice that in field use, batteries yield approximately 80-85% (80% shown below) of their rated (Laboratory Derived) amp-hours. This appears to be a common efficiency factor used throughout the electrical industry. This is not a reflection on any manufacturer, but the manner in which testing results are derived and used by most when it comes to marketing their products. We have provided typical differences below for your evaluation and use in determining your requirements. When calculating a house bank size requirement to fill one's needs, multiply your house bank amp-hour requirement by 125% (actual AH is apx. 80% of rated AH) in order to arrive at the correctly sized battery bank when using published battery rated amp-hours.

The graph on the left displays specifications from an owner's manual based on lab testing results under perfect tightly controlled conditions. The graph on the right is from actual observed field measurements performed by ZRD. Manufacturer lab testing reaches its 50% capacity level at 12.20 vdc. ZRD reached its 50% capacity at 12.05vdc. The disparity is due to the fact that the laboratory tested battery bank is starting at a higher state of laboratory initial charge that is not available or possible to achieve in a field setting.

| Capacity | 0 % | 20 % | 40 % | 50 % | 60 % | 80 % | 100 % |

| Manufacturer Specified voltage | 10.50 | 11.55 | 12.05 | 12.20 | 12.35 | 12.60 | 12.80 |

| ZRD Observed voltage | 10.50 | 11.25 | 11.80 | 12.05 | 12.25 | 12.55 | 12.80 |

| 4D AH available per Specifications | 0 | 42 | 84 | 105 | 126 | 168 | 210 |

| ZRD Observed AH available | 0 | 34 | 67 | 84 | 101 | 134 | 168 |

| 8D AH available per Specifications | 0 | 51 | 102 | 128 | 153 | 204 | 255 |

| ZRD Observed AH available | 0 | 41 | 82 | 102 | 122 | 163 | 204 |

|

|

The ZRD data (graph on right) was based on a typical daily consumption of 15 AH per battery per day (significantly less than the

20 hour rate). At the end of 6 days a recharge cycle was started to return the battery bank to its 100% recharge state - correctly (3-STAGE),

completely (100%), shore power (Stable) recharged. One is still using 50 - 100% (discharge - recharge) states, but the numbers are in

proportion to the manufacturer's specifications. If your rate of consumption (AH per day) is significantly greater than the manufacturer's or

ZRD test data, your will reach the various levels of discharge at a faster rate with a corresponding reduction in available amp hours.

Remember, deep cycle battery capacity is usually stated as a 20 hour discharge rate.. This means that if you divide the battery's amp hour

rating by 20 and consume this number of amps per hour, you will have a 100% discharged battery at the end of the 20 hour period. As an example,

a 100 AH battery will provide 5 amps for 20 hours.

When using power at discharge rates above its 20 hour rate, a battery will not supply its rated AH. It will reach 100% discharge in a shorter time period. The greater this increased rate is, the more significant the decrease in time to reach the 100% discharge state. Lastly, consider the following table.

When using power at discharge rates above its 20 hour rate, a battery will not supply its rated AH. It will reach 100% discharge in a shorter time period. The greater this increased rate is, the more significant the decrease in time to reach the 100% discharge state. Lastly, consider the following table.

CAPACITY AT VARIOUS DISCHARGE RATES

| Hours to Reach 100% Discharge of Capacity | 20 | 10 | 5 | 3 | 1 |

| Percent of Rating | 100 % | 89 % | 78 % | 66 % | 45 % |

If less than 20 hours passes before battery voltage falls to 10.5V you can still determine your capacity with some simple arithmetic. Using a 12 vdc

100 AH rated battery with a constant 5 amp load applied, takes only 10 hours to reach 10.50 vdc, you will have consumed 50 AH. This is the 10 hour

capacity. Dividing the 50 AH consumed by 89% (10 hour rate from the table above), you determine that the actual 20 hour capacity for this battery is

56 AH. This is either a defective battery, one that has not been maintained, or one that is very close to the end of its life. If that same battery

had consumed 85 AH (using a higher current draw of 8.5 amps over the same time period), the capacity for this battery would be 95.5 AH (85 AH

consumed divided by 89%). This battery would be significantly in better condition than the battery in the previous example.

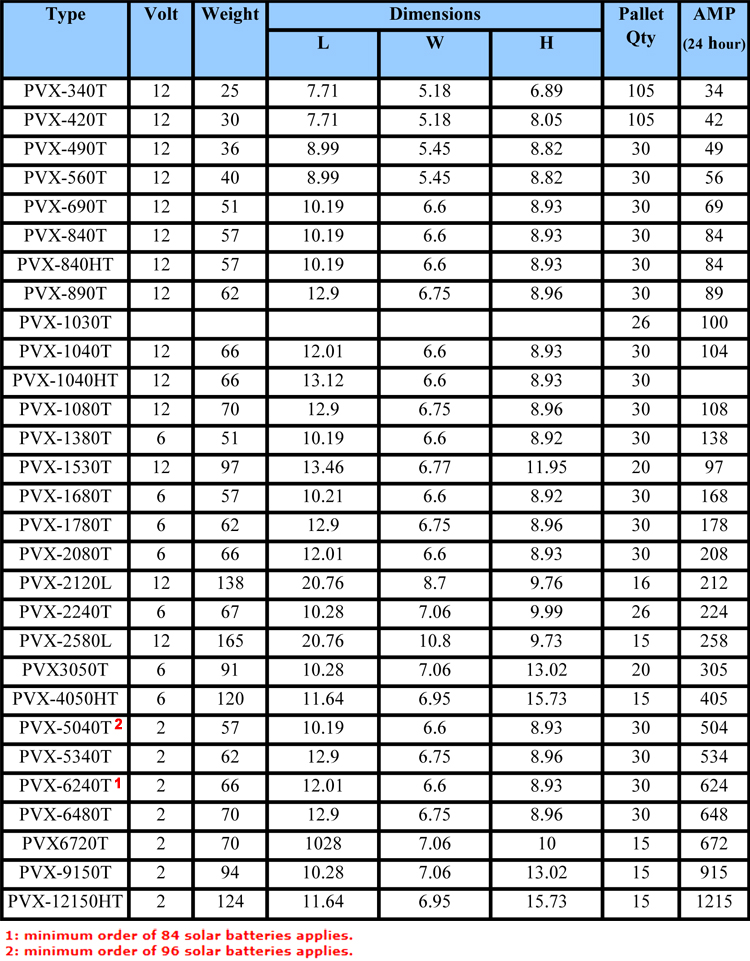

Dedicated Solar Battery information starts here

| Sun-Xtender AGM DEEP CYCLE SOLAR BATTERIES | ||

| ||

|

• ABSORBENT GLASS MAT

• VALVE REGULATED SEALED LEAD ACID (VRLA) • MAINTENANCE-FREE BATTERIES |

Designed for: RENEWABLE ENERGY STORAGE SYSTEMS

SOLAR, PV AND WIND, OFF GRID & GRID TIED SYSTEMS | |

Above information provided by Sun Xtender

Standard Terminals: All batteries with a "T" at the end of the part number incorporate M8 (copper alloy) threaded insert terminals

except as follows: PVX-340T & PVX-420T are M6 and PVX-2120L & PVX-2580L are "L" Blade (solid copper) terminals. All batteries are supplied with

silicon bronze bolts, nuts, and washers required for installation.

Optional (Copper Alloy) Terminal Installed at the Factory: Batteries with a "T" at the end of the part number (except PVX-340T & PVX-420T) are available with an optional factory installed "A" SAE automotive type terminal by adding the appropriate suffix to the end of the part number. For example, order PVX-1040TA instead of PVX-1040T.

Optional (Copper Alloy) Terminal Kit: Kits can be ordered for `After Factory` customer conversions of "T" type batteries (except PVX-340T & PVX-420T) by ordering P/N 6918 for the "A" SAE automotive post kit. Kit includes terminals and installation bolts required for installation.

Terminal Torque Values: [M6 use 35 in-lbs / 4.0 Nm] [M8 use 70 in-lbs / 7.9 Nm]

Handles: All batteries include built in lifting handles except the PVX-490T and PVX-560T.

Ratings: Capacity ratings are after 15 cycles and are stated at 77°F (25°C) to 1.75 volts per cell.

Optional (Copper Alloy) Terminal Installed at the Factory: Batteries with a "T" at the end of the part number (except PVX-340T & PVX-420T) are available with an optional factory installed "A" SAE automotive type terminal by adding the appropriate suffix to the end of the part number. For example, order PVX-1040TA instead of PVX-1040T.

Optional (Copper Alloy) Terminal Kit: Kits can be ordered for `After Factory` customer conversions of "T" type batteries (except PVX-340T & PVX-420T) by ordering P/N 6918 for the "A" SAE automotive post kit. Kit includes terminals and installation bolts required for installation.

Terminal Torque Values: [M6 use 35 in-lbs / 4.0 Nm] [M8 use 70 in-lbs / 7.9 Nm]

Handles: All batteries include built in lifting handles except the PVX-490T and PVX-560T.

Ratings: Capacity ratings are after 15 cycles and are stated at 77°F (25°C) to 1.75 volts per cell.

SUN-XTENDERTM BATTERY DESIGN FEATURES • Copper Alloy Terminals for improved electrical connections.

• No exposed lead terminals. This change was incorporated to improve environmental safety and health.

• Threaded insert terminals are recessed to prevent short circuits across battery connections.1

• New cover is flat top design. No protruding or exposed vent valves.1

• Built in lifting handles, except PVX-490T and PVX-560T.

• Reinforced container walls to reduce bulging.

• High Impact Strength Copolymer Polypropylene Case and Cover.

• Completely Sealed Valve Regulated Construction.

• Immobilized Electrolyte Non-Spillable.

• Maintenance Free Design Never Requires Watering.

• Absorbed Glass Mat (AGM) Micro-porous Glass Separators retain electrolyte.

• Flame Arresting Pressure Regulated Safety Valves.

• UL Recognized Systems Component.

• Positive Plates - Proprietary Lead Calcium Alloy- Negatives Plates - Lead Calcium.

• Low Self Discharge Rate Approximately 1 % per month at 25°C (77°F).

• Operate over a Wide Range of Temperatures from -40°C (-40°F) to +72°C (+160°F).

• Classified as "Non-Spillable Battery" for transport. Complies with DOT HMR49, Non-Hazardous Materials.

1 Threaded Insert "T" type Features.

Ratings: Capacity ratings are after 15 cycles and are at 77°F (25°C) to 1.75 volts per cell.

Charging Instructions: Initial charge or recharge - 2.37 to 2.40 volts per cell at 25° C (77° F). Float charge - 2.20 to 2.23 volts

per cell at 25° C (77° F). Conditioning charge - 2.58 volts per cell at 25° C (77° F). Temperature compensation - 4.00 mV. per cell

per degree C [Reference to 25° C (77° F)]. This is for battery temperature (not ambient temperature) and is useful for battery temperatures

from 0° C to 40° C. Contact Concorde Battery Corporation for temperatures that exceed this range.

Never install batteries in a sealed compartment or container.

Specifications subject to change without notice.

For more information, contact ZRD.