|

|

Power Take Off (crankshaft) Pulleys |

Unfortunately, Due to Production limitations, many PTO pulleys may require an extended lead time or

may no longer be available.

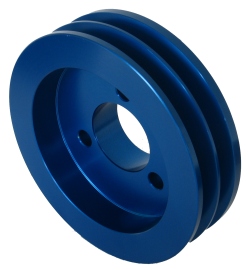

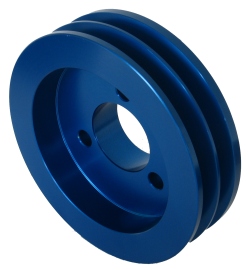

The first two rows of pictures show typical PTO (Power Take Off) pulleys we manufacture that allow for the attachment of a High Output Second (dual)

alternator to most engine manufacturer crankshafts. It is available in twin V-belt or 8 Groove Serpentine configurations. The PTOs on the top (first)

row show an optional ZRD blue finish. The picture on the middle row shows the standard (normal PTO) finish. We stock PTO pulleys that fit (bolt on to)

most Yanmar engine crankshafts. For other engine manufacturers, we make the PTO on demannd. Standard delivery is 2-6 weeks.

Below the standard crankshaft PTOs (bottom - third row) are examples of three custom PTOs. The first picture is a 4 sheave PTO pulley that is designed for

significantly larger engines that are able to feed multiple power take off options. This type of PTO requires additional horsepower and the availability

of room around the engine in order to allow for the attachment of the options.

In the middle the photo shows how ZRD is able to custom create (special order) a PTO pulley or a new replacement pulley that will be the combination of

the main (original) crankshaft pulley (one or two sheaves) plus a 2 sheave PTO. The end result is a new bolt replacement pulley for the crankshaft with

three or four sheaves that will accommodate all of your needs to mount v-belts. This example was designed and manufactured to have a single 3/8" sheave

to match the original crankshaft and then add two 1/2" PTO sheaves.

Pictured at the far right is an example of a customer's requirements that needed a very specific solution. It had very different specifications than is

normally required of standard PTOs. Note there are multiple sheaves with different diameters and widths. The finished PTO is shown bolted on to

the existing engine crankshaft pulley. Part of the PTO fits inside the crankshaft pulley with very tight tolerances. It fits like a tight leather racing glove.

The crankshaft pulley and the PTO are bolted together with Titanium bolts.

$ Pricing

All of our Pulleys (Standard and Custom) are custom made by hand locally at ZRD in the USA (truly Made in USA) on CNC machines. Cost of materials, labor,

and especially machine time is extremely expensive. It is a very detailed and expensive manufacturing process. The expenses of producing one-offs PTOs requires

considerably more expense than the standard prospective customer may know and is difficult to explain without them knowing what is involved when they place their

initial inquiry. Our "in-stock" PTOs are slighly less expensive due to quantity production runs, but still more expensive than most realize. |

|

|

Specialized Pulleys

Depending on your situation, we may ofer to custom create (requires a special order) a new replacement

pulley for most items attached to your power plant or accessories in order to have a proper total solution.

The costs associated with this option varies widely depending on what is required, complexity of fabrication

and the man hours that may be required. A free phone consultation is always available in order to get initial

estimates for your situation.

Special Note:

The following service is not provided to all manufacturers' engines. It is displayed here to show ZRD capabilities. This limitation is due to

the additional side loading (mostly on water pump components) created by alternators that exceed 94 amps. This has reportedly led to premature

engine failures. ZRD will provide this specific service only if authorized by the original engine manufacturer. This restriction is due to factors

beyond our control that may lead to overloading and failures.

The first photo (top right) is an installation that had it's 3/8" single sheave crankshaft pulley modified to become a 1/2" single sheave version and a new

1/2" water pump pulley was made to replace it's previous 3/8" one. |

|

|

|

|

Another example is shown in the second and third photos (bottom right - before, far right - after) of a Westerbeke 44 that was modified from a single 3/8" pulley

arrangement to a double 3/8" pulley and belt design. This allowed a custom designed ZRD 120 amp alternator to be installed properly. A ZRD 140 amp solution was

also possible. Again, remember in most cases, the upgrade replacement of an originally installed OEM alternator is restricted to 94 amps.

The important item of significance to note here is that the modified crankshaft pulley and the new water pump pulley were created in such a way as to ensure the

alignment of the newly created sheaves with each other and the replacement alternator's sheave. This technique is applied when we design PTOs / Replace Crankshaft

Pulleys for PTO attachment for ZRD Second (dual) Alternator High Output soultions. In order to ensure a proper fit, you will need to send us your existing

pulley(s) and any associated & co-located hardware (washers, bolts, balancers, ...).

Special Note:

If any hardware sent to ZRD is not easily replaceable via the manufacturer or a parts supplier, ZRD must be notified in advance prior to shipment to ZRD. ZRD's

only accepted liability is to a pre-arranged agreed amount ($) in the event should damage or loss of non-replaceable customer hardware occur after ZRD receipt of

customer hardware and prior to customer's receipt of a completed order. The completed order shipment will contain all customer supplied hardware in addition to the

ordered components. If no order is placed after ZRD receives a customer's hardware, customer agrees to assume full sole responsibility for return shipment charges

and any and all liability for loss or damage. If customer does not request the return of any of his supplied hardware within thirty (30) days of receipt by ZRD,

customer relinquishes all claims to supplied hardware. Under no circumstances, shall ZRD's maximum accepted liability for any loss or damaged customer hardware to

ever exceed $500.

ZRD Alternator Pulleys (In Stock - Special Order)

The following ZRD stock pulleys are machined to work in conjunction with standard engine or ZRD custom PTOs to enable/ensure correct engine/alternator

operation range. They are for use with large and X-large case high-output alternators with 7/8" (0.875") shaft bore. We also have an assortment

of single sheave pulleys for standard shaft bore (17mm = 0.67"). Contact us for details.

Dual V, 2 - 1/2" Sheaves

| Part Number: |

Diameter |

| ZP782240 |

2.40" |

| ZP782270 |

2.70" |

| ZP782300 |

3.00" |

| ZP782310 |

3.10" |

| ZP782325 |

3.25" |

| ZP782335 |

3.36" |

| ZP782350 |

3.53" |

| ZP782425 |

4.25" |

Serpentine, 8-Groove 1.125" Width (depth)

| Part Number: |

Diameter |

| ZP78S240 |

2.37" |

| ZP78S270 |

2.76" |

| ZP78S300 |

3.00" |

| ZP78S340 |

3.43" |