Assuming your boat is large enough (a relative term) to require extended DC capacity, the following discussion should answer most questions. The reasoning for

the approach below is to put to use the drive engine for charging ONLY when under load (such as motoring). The battery bank is to hold you over in between. This

will be calculated in step one.

You do not want to use your engine for charging at anchor or it will be the most expensive generator you purchase. Its life will be shortened immeasurably

and cost much more on maintenance. Extended no load operation of a diesel engine will "glaze" the rings and unfortunately will cause oil blow by at some point.

The exhaust system will also start sooting over. The tell-tale sign of this is that the engine exhaust will start to blacken. This is an often occurrence

to overland trucks when their drivers pull off to sleep in their cab overs and leave the engine running as a normal practice (to run the A/C or heaters....).

We have found that a lot of the cross-country truckers are adding small generators to their rigs to preclude this from happening. The key point to note is the

no-load, extended period engine run time. An occasional or short period should not be a long term factor. For those vessels that do not have a generator installed

(regardless of reason), a short term or VERY occasional way to charge at anchor is the following. Ensure your anchor is set properly and then engage your engine's

propeller in reverse with a typical rpm range between 1,500 to 1,800. Combined with the added prop load, propulsion engine alternator charging will not cause

engine damage, but has other associated deficiencies for another discussion. Remember, this is an occasional remedy! It should not be your standard routine for

charging when on the hook.

As we just discussed, if room allows, and more capacity is desired, a dedicated Generator is required. Preferably a ZRD DC Generator would be used instead of an

AC Generator enabling minimal run times, low noise, and significant fuel savings. Click on

Why choose a DC Generator over an AC Generator?

to read the details.

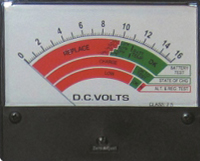

Everything may be run from with the house battery bank (an inverter will provide 120vac as needed) being the power source. The Generator

only needs to be run when the battery bank needs to be recharged. A properly sized battery bank will provide all of the needed power to run all equipment,

even appliances. Again, charging only takes place when the battery bank gets discharged to apx 12vdc.

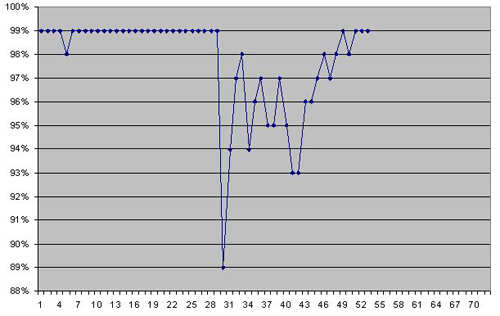

First, you need to calculate your demand for DC power (add up the max DC amps consumed between charge cycles). This amount needs to be doubled because you

do not want to go below 50% on a regular basis or the battery life will degrade. When you are calculating, consider worst case, such as anchoring for extended

periods. Experience and observation puts this number at 750Ah on the low side, 1000Ah as average and anything higher as great. If you are in a power vessel

instead of sail that has high draw items, this will be even higher. You may be limited by the room on hand. 1000Ah takes 4 8D batteries.

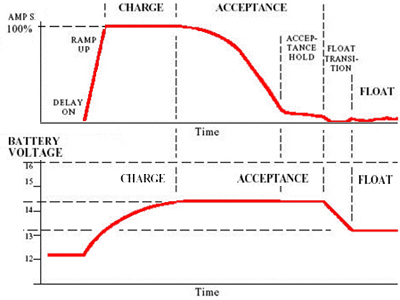

Second, now that you have the amount of DC amp hours required, double that number and divide the result by your charging sources capacity (standard

alternator, "inverter", generator…) and you will have the approximate time needed to do the charging. With this in mind, it brings up whether

your sources are adequate.

This is usually the point, where one decides/figures that one does need that second High Output Alternator (See link on sizing). This is truly the best

approach. Keep your standard low amperage alternator to charge your starting battery. Use the second High Output Alternator to charge the house bank. With

the correct wiring and switches, there are backups.

Also, this is the point where one may discover that one's desires or needs may be beyond the physical size and limitations produced by their vessel. In this

situation, one has to accept these limitations and use the vessel with this in mind. Do not go beyond the limitations or comfort or safety will be compromised.

The standard alternator or an upgrade to a ZRD 94amp (12vdc) High Output Alternator is your only smart, safe option. Unlike other vendors, we will let you know

if you are close to this situation and recommend not purchasing a renovation and living within the vessel's limitations until you are ready for a vessel

upsize that will allow your desires to be installed and met.

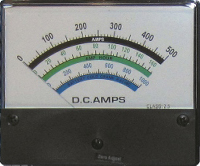

Third, power drain. Calculations dictate that 2 HP is required for every 100 DC amps generated. The industry uses an efficiency factor of 50% (Our testing

finds that most alternators are more efficient than 50%, but each should be verified for your use) for motors/generators. A ZRD High Output 220amp Alternator

requires considerably less than others at full output, due to their design and manufacture. This should not be a problem for most inboards. We have installed them on

25 hp sail drives. Up to 94 amps requires a single 1/2" belt and over requires two 1/2" belts. Normal installation requires a switch in line to

the regulator (another reason for an external regulator) to switch it off for many reasons, but mostly in the event you need the extra power delivered to the

propeller - on smaller engines less than 50hp.

Fourth, a battery discussion. If you have wet cells, use them until they die or if you can, sell them. Then, get good (not all brands are the same) AGM

batteries. The reason is simple - You would defeat the purpose of high output charging. AGM batteries are designed to take high charging rates and wet cells

are not. I would not exceed a charge rate in excess of 100 amps with the typical wet cell battery bank. With AGMs, there is no limit except for the max

ampacity for a given cable (normally 2/0 or 4/0) size (wire ampacity).

Lastly, Brackets and Mounting. It is not complicated - It applies to all engine manufactures. This is our specialty. First a bracket holds the alternator

and provides for belt tension and adjustment. This assembly is then attached to the engine via angle iron attached to the motor mounts or block. A double

groove or serpentine PTO (power take off pulley) is attached to the main crankshaft to turn the second High Output Alternator.

With the basic approach discussed, you should have multiple sources of reliable power. You may even run your Air Conditioning off of the batteries with

NO PROBLEM. We hope this has helped those of you that are confused by all the hype out there.